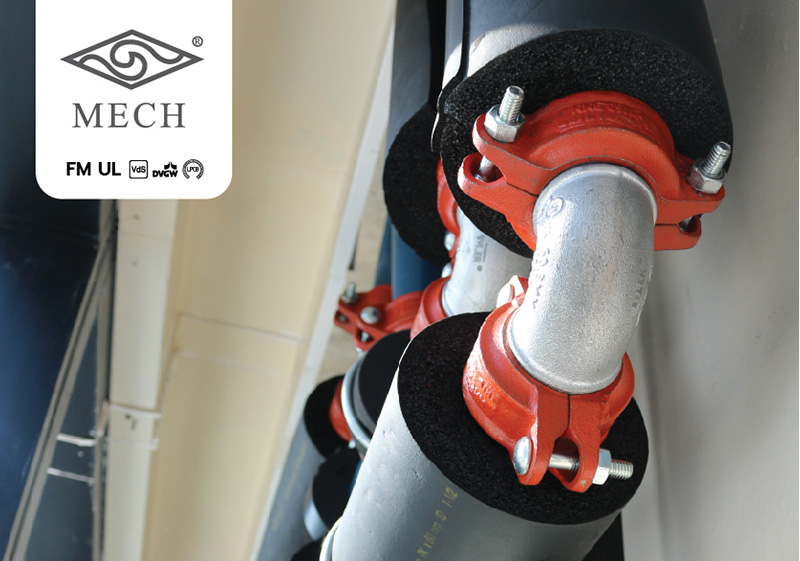

Supporting and Protection of A Grooved-End Pipe System

Supporting and protection of a grooved-end pipe system refers to the general term for fixing, supporting, anti-vibration, anti-corrosion, and thermal insulation measures taken to ensure the quality, safety and service life of the pipe system.

Design, Construction, and Acceptance Requirements for Pipeline Fixing and Supporting

1. Design of Pipe Support and Hanger

Pipe supports and hangers for grooved-connection pipeline engineering should be strengthened. Supports and hangers should be provided on both sides of joints and also on both sides of upstream and downstream connection joints of pipe fittings such as tees, crosses, elbows and reducers.

Fixed supports and hangers should be installed in following positions of grooved-connection pipeline engineering:

1.1 The bottom of the inlet vertical-pipe.

1.2 The bottom where the pipe turns and redirects to the elbow.

1.3 The tee or cross position of outgoing branch pipe of vertical pipe.

1.4 The position of the riser that needs to support the weight of the riser due to its long free length.

1.5The part where the outgoing branch pipe of horizontal pipe is connected to pipe fittings such as branch pipe joints, tees, crosses, elbows, etc.

1.6 The part where the pipeline is equipped with a compensator to control the pipeline expansion and contraction.

1.7 Other parts of the pipeline that need special reinforcement.

2. Construction and Acceptance of Pipe Support and Hanger

-

2.1 General Installation: Supports and hangers should be installed firmly according to design requirements, and their installation positions must be correct.

2.2 Installation Control Regulations:

2.2.1 When the floor height is not greater than 5m, one vertical-pipe support and hanger shall be installed on each floor. When the floor height is greater than 5m, there should be no less than 2 on each floor. When there is no branch pipe on the vertical pipe, the installation height of the support and hanger should be 1.20~1.60m from the ground.

2.2.2 One support and hanger shall be provided for each straight section of the horizontal pipe. The allowable spacing of the support and hanger shall not be greater than provisions in the following table.

Table 1: Allowable spacing of non-insulating horizontal-pipe support and hanger (m)

| Norminal Size (mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Span between supports (m) | 3.7 | 3.7 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 |

Note: For insulating pipes, the distance between support and hanger should be reduced correspondingly according to the influence of the weight of the insulating material installed on the pipe.

-

2.3 Spacing Near Joints: The horizontal-pipe supports and hangers shall be arranged on both sides of joints and also on both sides of upstream and downstream connection joints of pipe fittings. The net distance between the support and hanger and the joint should not be less than 150mm, and should not be greater than 300mm.

2.4 Fixation and Adjustment: During pipeline installation, supports and hangers should be fixed and adjusted in time, and temporary supports and hangers should not be used. The support and hanger should be in close contact with the pipe. The sliding surface of the sliding bracket should be clean and flat, and there should be facilities to prevent falling off.

2.5 Elevation: The installation of supports and hangers shall meet the elevation requirements of pipeline installation.

3. Standards and References

Other requirements of the support and hanger shall be implemented in accordance with the NFPA 13, Standard for the Installation of Sprinkler Systems, 2019 edition.

- The minimum requirements for pipeline design, installation, shockproof, anti-corrosion, and antifreeze shall be implemented in accordance with the following standards:

- NFPA 13: Standard for the Installation of Sprinkler Systems, 2019 edition.

- NFPA 13R: Standard for the Installation of Sprinkler Systems in Low-Rise Residential Occupancies, 2019 edition.

- NFPA 14: Standard for the Installation of Standpipe and Hose Systems, 2016 edition.

- NFPA 15: Standard for Water Spray Fixed Systems for Fire Protection, 2007 edition.

- NFPA 24: Standard for the Installation of Private Fire Service Mains and Their Appurtenances, 2019 edition.

- ASME B31.1: Power Piping, 2020 edition.

- ASME B31.3: Process Piping, 2018 edition.

- ASME B31.9: Building Services Piping, 2017 edition.

- Inspection and Maintenance: The inspection, test and maintenance of the pipeline shall be carried out with reference to NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, 2020 edition.

สนใจสอบถามรายละเอียดเพิ่มเติมได้ที่